The electrostatic sprayer to improve the scope of surface disinfection.

What is an electrostatic sprayer?

Electrostatic sprayers are equipment which, as their name suggests, are mainly used to spray liquid disinfectants, fungicides and pesticides.

They are used to spray the surface to be treated with the biocide disinfectant that we have selected and which is water-based. It can be applied to all types of surfaces, equipment and furniture, such as doors, handles, sanitary ware, tiles, electronic devices, etc. Always with care and with previous training and learning how to use the electrostatic equipment.

In what types of installations and sectors can electrostatic spraying be used?

In all types of installations and sectors, e.g. food industry, offices, hospitals, hotels, transport, schools, gymnasiums.

Main features and benefits of an electrostatic sprayer.

Droplet size does matter.

The ideal droplet size when spraying an electrostatic sprayer should be larger than 30 microns, the average recommended droplet size is 40 microns. This means that the droplet has the correct volume to receive enough electrical charge to be correctly charged and a weight that does not allow it to remain suspended in the environment and to stick to the surface.

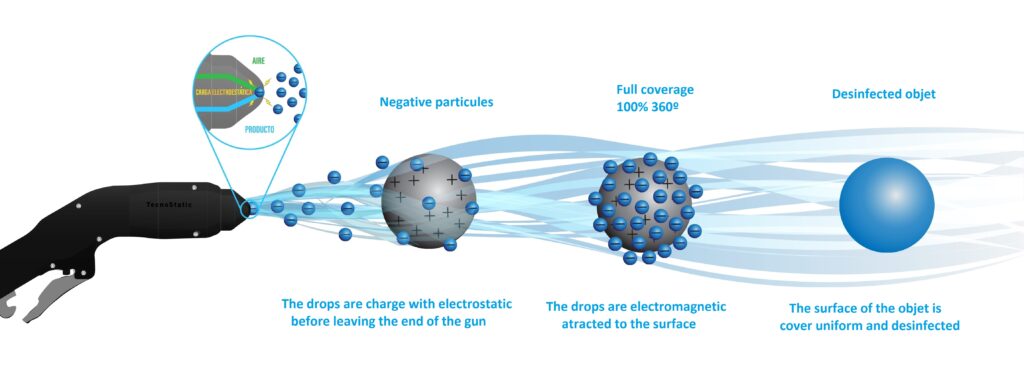

When the liquid is expelled through the nozzle of the gun, it breaks and generates thousands of droplets, which in turn are charged with negative ions. These droplets act as if they were a magnet, they are attracted to the surface or object and stick to it without leaving gaps and decontaminate.

When the droplets are looking for a surface to adhere to, they look for a free space and only when the entire surface is covered do they attach themselves to each other. This ensures that the surface to be treated has been correctly sprayed with the disinfectant.

On the other hand, it has the capacity to cover an object 360º, as long as the diameter of the object or surface we are spraying is an average size of 10/15 cm.

The electrostatic spraying technology is able to surround and cover the object from the front and rear, which allows us to disinfect those areas where we could not reach otherwise, substantially improving the scope of disinfection, since those parts that until now we could not reach with electrostatic spraying we do reach and we decontaminate and disinfect.

If we have already mentioned that the reach with the capacity to cover a surface 360º improves the reach of the disinfection, the same happens with the assistance of the air that the TecnoStatic equipment integrates.

TecnoStatic electrostatic spraying equipment is air-assisted, this allows the disinfectant to be transported towards the surface or object and penetrate all surfaces and areas such as grilles, cracks, crevices or spaces where it is impossible to reach manually or with other traditional spraying systems and to be able to carry out a correct disinfection in these spaces and critical points.